Which electric bike Motor is Best ? gears motor?mid drive motor? front motor?

The e-bike motor is integral to the frame and cannot be easily swapped like other components, so here’s everything you need to know before you buy your next electric bike

The best e-bike motors will balance the scales between power and weight, to offer maximum pedal assistance without weighing the bike down and holding it back. Of course, e-bike motors come as part of the bike itself and aren’t yet a component that you can swap out and upgrade, Best mid drive electric bikes so it’s important to know what you’re getting into when choosing from the best electric bikes.

The e-bike has well and truly established itself as a valuable part of cycling’s future. Where once the market was dominated by electric bikes for commuting, it is now rich with the best electric road bikes and the best electric gravel bikes as well.

For all the benefits of e-bikes, they can also create confusion and ownership anxiety, triggered by the steep technology curve powering these bikes along. As with all things electric, the logic is that a delayed purchase is best, allowing you to benefit from capturing the latest technology.

But if you have no idea where to even start, then we’re here to help dispel some of the confusion surrounding the best e-bike motors, and what they’re capable of.

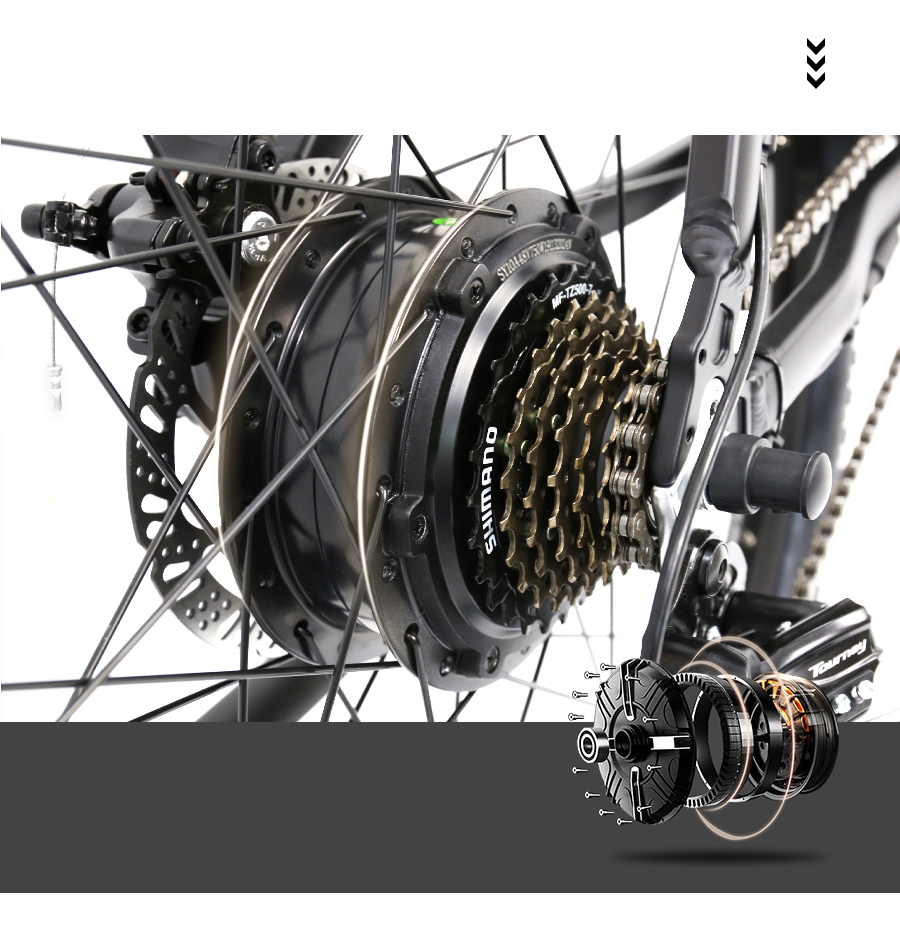

An electric hunting bike can be equipped with any of the three types of motor, each delivering varying performance on different terrains. The rear hub motor (placed in the back wheel) produces massive raw power and is a practical choice as it requires less maintenance and is usually priced more affordably. However, its low torque makes it weak when climbing up a trail.

The mid drive motor (located between the bike’s pedals) has a stronger torque compared to the rear hub motor. Thus, it can climb better and more easily. On the downside, bikes with this type of motor could be costlier and require more maintenance.

Lastly, the ultra mid drive motor provides the best control and performance among the three types. As the mid drive motor’s upgraded version, it is more powerful and efficient especially when traversing an uphill. But as expected, it comes with a greater price tag though it requires less maintenance.

Bafangs internal labeling system calls this the MM G510.1000, and it’s design makes several improvements over my favorite drive, the BBSHD. The BBSHD is a kit that slides into just about any frame you like, but the Ultra Max requires a proprietary shell to mount it (see below).

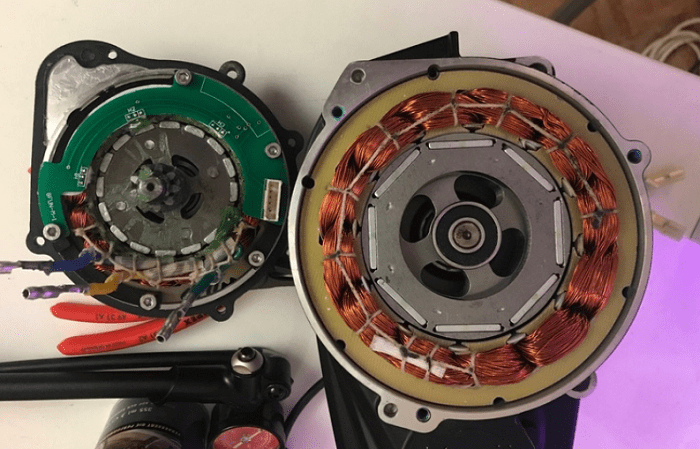

The first thing that pops out at the casual observer is that the Ultra has a larger diameter motor. This increases the amount of leverage that the magnets exert onto spinning the rotor, without any additional watts applied to it, compared to the same watts being applied to a smaller diameter motor with the same copper mass. The other thing that this helps is the efficiency, since the “tangential magnet speed” is faster for a given RPM.

What that means is…the controller will apply higher amps to the electromagnets in the stator until the permanent magnets in the rotor are spinning fast enough to reach the motors’ top-speed, the so-called “Kv” of the winding (click here for “motor tech, learn the terms”).

The faster the magnets pass by each other, the shorter the pulses of watts are…that are applied to the electromagnets. Using lots of small pulses ‘can’ provide the same total power that is applied, compared to using fewer long pulses, but…using long “on” pulses will heat up the MOSFET’s in the controller, and also the electromagnets in the stator.

Be aware the Ultra Max stator is narrower than the BBSHD, but the diameter is larger enough that it still does have more copper mass.

Another thing that is worth noting is that the BBS02 in the picture above uses what’s called “Surface Permanent Magnets” / SPM on the rotor, and the Ultra (along with the BBSHD) uses a style that inserts the magnets a small distance away from the surface of the rotor. This style is being seen more often these days, and it’s called an “Interior Permanent Magnet” motor / IPM.

This design allows the magnets to run cooler, which is important because one of the limitations on how many amps a motor can use is the heat that is generated by “eddy currents”. The stator core is made from a stack of very thin steel plates in order to reduce eddy currents, which are generated anytime a ferrous metal is rapidly passed through a magnetic field.

Using a stator-core that is made from thin laminated plates (coated with a lacquer to electrically isolate one plate from the other) is a cost-effective way to accomplish a limitation of any eddy current heat, but…unlike the laminated stator-core, the magnets are solid chunks of metal. With the older SPM motor designs, the magnet body itself becomes a source of waste heat.

With an IPM, the permanent magnets will “magnetize” the slim section of steel between them and the electromagnets in the stator. This keeps the magnetic field strength in the air-gap at an acceptable level, while still placing the actual permanent magnets a short distance away from the air-gap. Permanent magnets can lose their magnetic power if they get too hot, so…by doing this, you can use more “temporary peak” amps without overheating the magnets.

hotebike

hotebike