Do you know the difference between brushless motor and brush motor

Comparison of brushless and brushless motors

The difference in electrification principle between brushless motor and brushless motor: brushless motor USES carbon brush and commutator to carry out mechanical commutator, while brushless motor USES hall element induction signal to complete electronic commutator by controller.

Brushless and brushless motors have different electrification principles and internal structures. For hub motors, the output mode of motor torque (whether it is decelerated by the gear reducer) is different, and its mechanical structure is also different.

1.Internal mechanical structure of common high-speed brush motor. The hub type motor consists of a high-speed brush motor core, reduction gear set, overrunning clutch, hub end cap and other components. The high speed brush and gear hub motor belongs to inner rotor motor.

2, the common low speed brush motor internal mechanical structure. This hub-type motor is composed of carbon brush, phase converter, motor rotor, motor stator, motor shaft, motor end cover, bearing and other components. Low-speed brushless hub motor belongs to outer rotor motor.

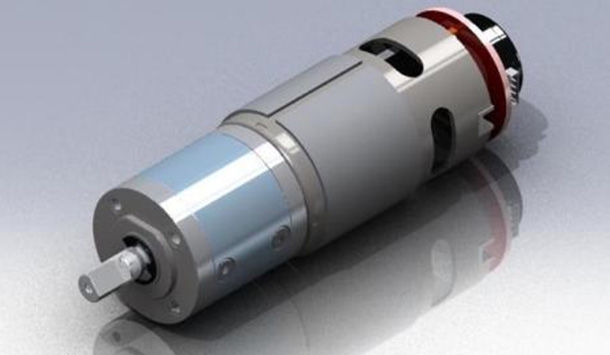

3.Internal mechanical structure of common high-speed brushless motor. The hub type motor consists of a high-speed brushless motor core, planetary friction roller, overload clutch, output flange, end cover, hub housing and other components. The high speed brushless hub motor belongs to the inner rotor motor.

4.Internal mechanical structure of common low-speed brushless motor. The hub type motor is composed of motor rotor, motor stator, motor shaft, motor end cover, bearing and other components. The low speed brushless and gear hub type motor belongs to outer rotor motor.

The working principle of motors

Motors is a device that converts electrical energy into mechanical energy. The rotating magnetic field is generated by the current coil (stator winding) and used for the squirrel cage closure aluminum frame to form the magneto-electric power rotating torque. According to different power sources, electric motors are divided into dc motor and ac motor. Most electric motors in the power system are ac motors, which can be synchronous motors or asynchronous motors (motor stator magnetic field speed and rotor rotation speed do not keep synchronous speed). The motor is mainly composed of stator and rotor, and the direction of force movement of the conducting wire in the magnetic field is related to the direction of the current and the direction of the magnetic induction line (the direction of the magnetic field). Motor working principle is the magnetic field on the force of the current, make the motor rotation.

The main characteristics

Brushless dc motor is widely used in electric vehicles because it has the following two advantages compared with traditional brushless dc motor.

(1) long service life, maintenance-free and high reliability. In a brush dc motor, because the motor speed is higher, brush and commutator wear faster, the general work around 1000 hours need to replace the brush. In addition, the technical difficulty of the reduction gear box is greater, especially the lubrication problem of the transmission gear, which is a big problem in the current brush scheme. So there are brush motor noise, low efficiency, easy to produce problems such as failure. So the advantages of brushless dc motor are obvious.

(2) high efficiency and energy saving. Generally speaking, the efficiency of brushless dc motor can be higher than 85% due to the absence of friction loss of mechanical commutation, consumption of gear box, and loss of speed regulating circuit. However, considering the highest cost performance in the actual design, in order to reduce material consumption, the general design is 76%. The efficiency of brushless dc motors due to the consumption of gearbox and overrunning clutch is usually around 70%.

Common faults

Common faults with brushless dc motors are usually examined from their three components. When the fault location is not clear, the motor body should be checked first, followed by the position sensor, and finally check the drive control circuit. In the motor body, may appear

The problem is: A, motor winding contact bad, broken or short circuit. Will cause the motor not to turn; The motor can start in some positions, but cannot start in some positions; The motor is out of balance. B. demagnetization of the main magnetic pole of the electric motor will make the torque of the motor obviously small, while the no-load speed is high and the current is large. In the position sensor, the common problems are hall element damage, poor contact, position change, will make the motor output torque smaller, serious will make the motor does not move or vibration back and forth at a certain point. The power transistor is the most prone to failure in the drive control circuit, that is, the power transistor is damaged due to long-term overload, overvoltage or short circuit. The above is a simple analysis of the common faults of brushless motor, in the actual operation of the motor will be a variety of problems, inspectors should pay attention to not exactly grasp the situation, not at random power, so as not to cause damage to other components of the motor.

hotebike

hotebike